The laser alignment is crucial for the equipment and machines that are used in big industries. It will improve and enhance their overall performance. To maintain these machines and equipment’s alignment, you should better choose a laser alignment method that enhances the overall performance.

Laser Alignment:

To make a machine appropriately running for long, you will have to consider using the latest laser alignment technique to enhance the overall performance. The better a machine will be aligned, the better it will work. In this way, if the performance of a machine will be perfect, productivity will also increase.

Get unique suggestion about using an easy laser belt alignment tool:

It is crucial for a business owner to timely pay attention to the working mechanism of a machine and if it is not performing well because of misalignment, he or she should timely get it aligned best electrical maintenance also.

If the owner will not fix these problems on time, they may pay high prices when the misalignment would have made a machine highly malfunctioning. To make the machinery of your workplace perform in the best way for the long run, the owner must consider using an easy laser belt alignment tool.

There would be some workers that will feel it tough to handle these types of new tools as they would not be expert at it. It will be better for the owner to consider hiring a company’s professional services with significant experience using this particular tool to align the machinery. These professionals will align the shaft and provide professional suggestions to maintain the performance of the machinery for the future.

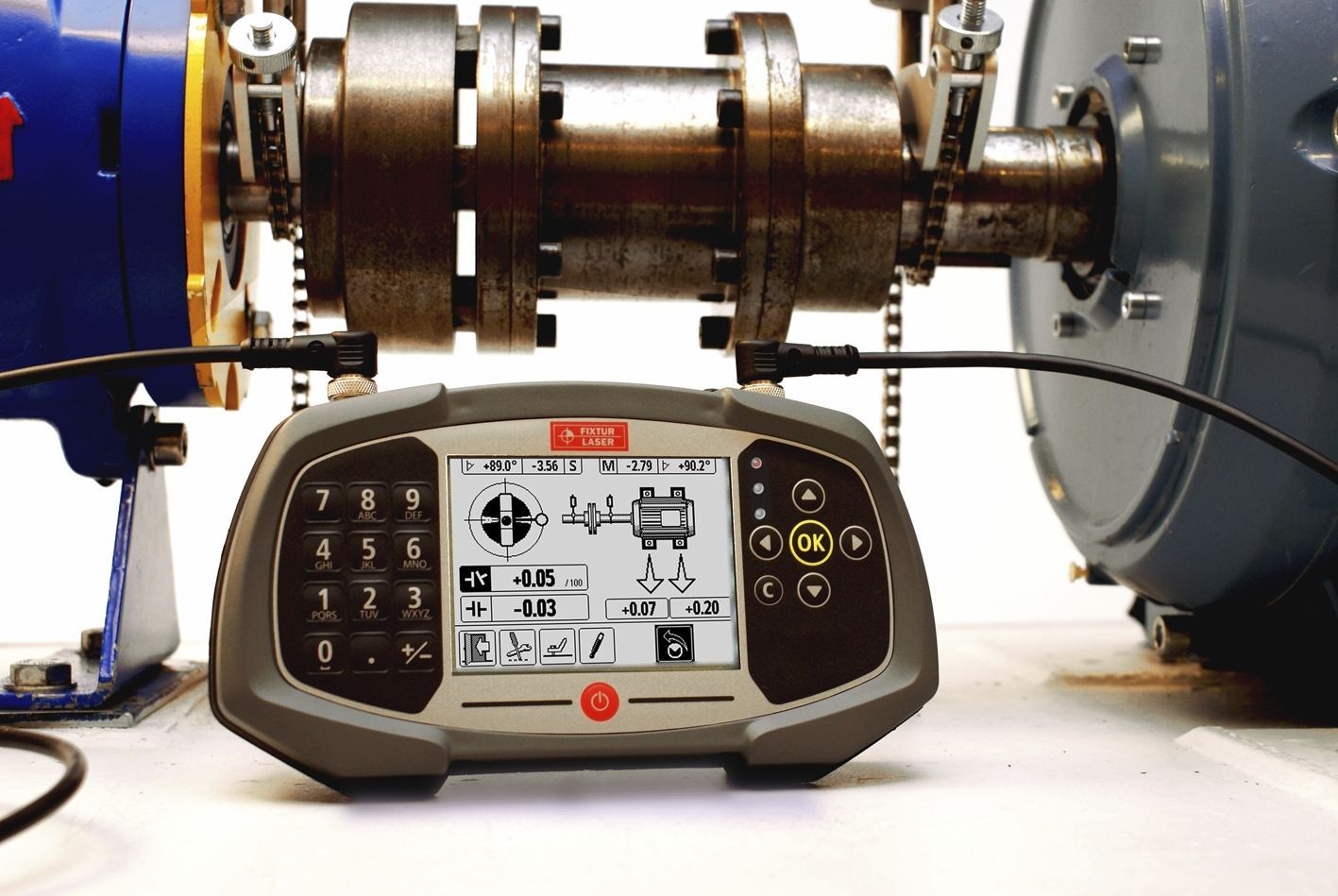

One of the significant benefits is using the laser alignment tool for the shaft to analyze the misalignment and set the machine’s accuracy and alignment by using the laser. Another benefit of using this tool is a misalignment of the shaft within the device will also be fixed.

Using laser alignment can be highly beneficial for an industry:

If a machine becomes misaligned, it will face significant wear and tear, and the worker working on it will have to consume a lot of energy on fixing it. If a machine is working hard, then it will consume increased energy. In this situation, you will have to pay for a long run against power consumption.

Therefore, using an easy laser alignment will reduce unnecessary wear and tear on bearings and seals, saving you from spending a lot of money. If you have a machine that requires you to change the bearings and seals every couple of months, then it’s time to consider the alignment of the machinery like shaft alignment.